Tensor-ΣΔ For Pressure

Designed for Scale – CPSS

Capacitive Pressure Sensing Skin

Capacitive Pressure Sensing Skin

CPSS Introduction

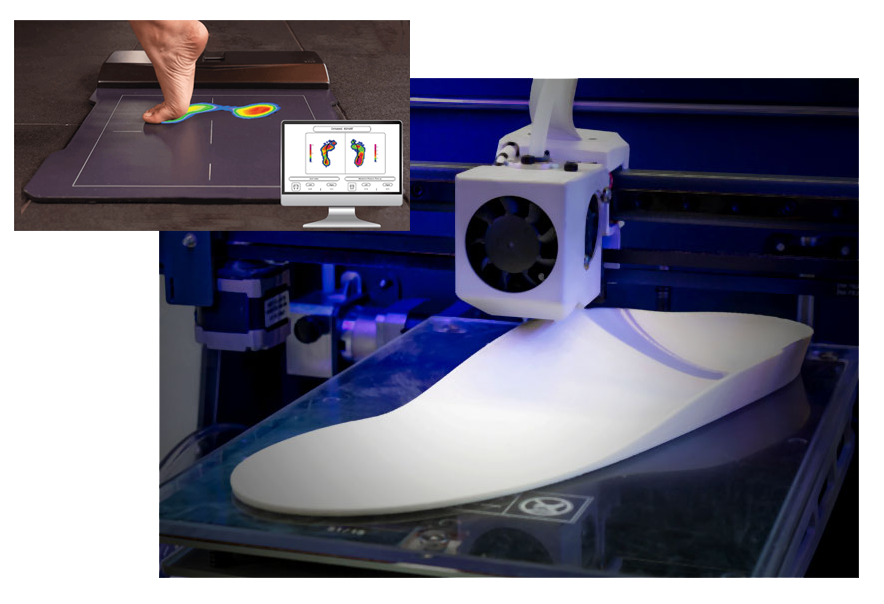

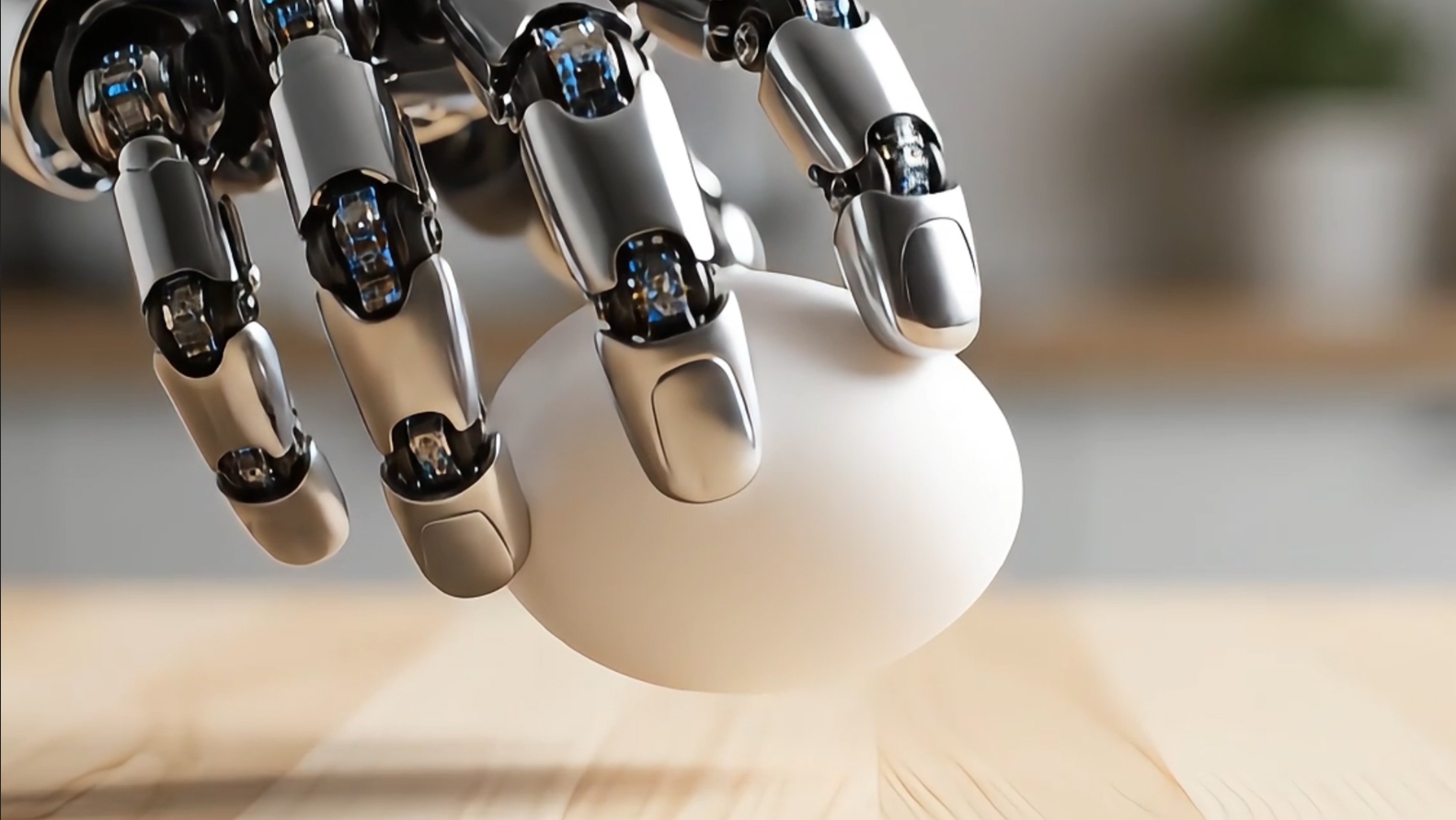

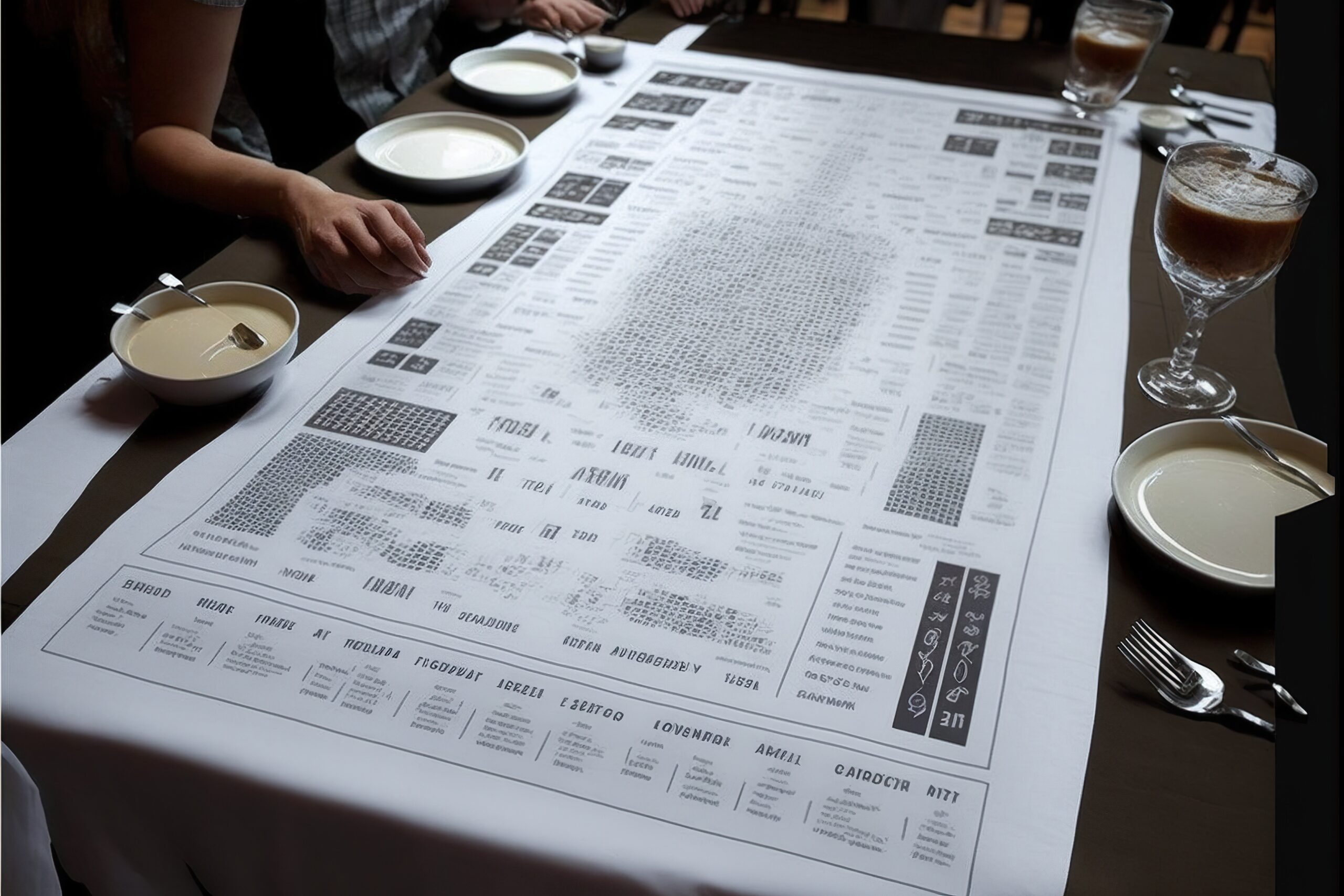

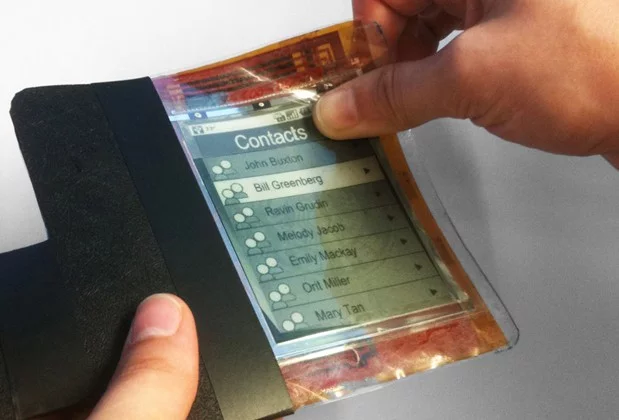

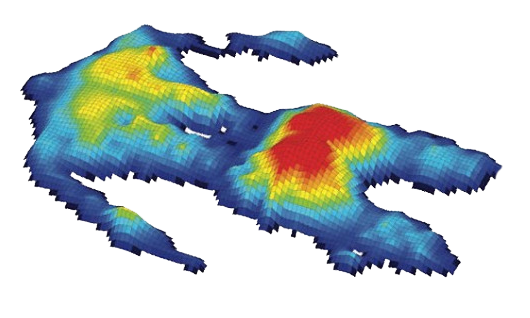

CogniSense Labs and its team specialize in capacitive sensing and announces its CPSS, pairing state of the art Tensor-ΣΔ silicon with edge native AI to grant machines an organic sense of feel. By layering high density sensor arrays with adaptive machine learning, the platform detects subtle pressure gradients and contact patterns with human-like precision.

This intuitive skin intelligence transforms raw tactile input into predictive insights in real time, enabling safer human-machine collaboration and nuanced physical interactions within complex, high-stakes environments like health and wellness, merchandising, and consumer electronics.

CPSS Advantages

| If your priority is… | Choose… |

|---|---|

| Lowest Cost | Resistive |

| Highest Precision | Optical |

| High Precision / Wearability / Durability | CPSS |

| Instant Impact Detection | Piezoelectric |

| Electromagnetic Immunity | Optical |

Tensor-ΣΔ Competitive Advantages for Pressure Sensing

- Sigma-Delta Drive Architecture: The advanced sigma‑delta control architecture enhances conversion accuracy by using high‑order noise shaping and oversampling techniques to achieve superior resolution and low distortion.

- Low Power: Ideal for battery-powered or always-on monitoring (e.g., hospital bed overlays, wearables, portable health and wellness devices).

- Static Force Accuracy: Superior for prolonged pressure mapping (e.g., preventing bedsores / injury).

- Large-Area Scalability: Thin, flexible stack suits roll-to-roll manufacturing for bed-sized films.

- High Performance Variants: Technologies like SigmaSense (related to CPSS) provide exceptional SNR and noise immunity, outperforming traditional resistive arrays.

- Minimal Wear: Non-contact sensing (capacitance change via compression) leads to better longevity than contact-based resistive.